品牌

其他厂商性质

所在地

性能特点

1.省时高效:节省人工叠纸时间,相对原先单张工艺可提高200%机器速度;

2.浪费率低:减少因单张分切而多余的纸张以及因纸张厚薄引起的损耗;

3.节能:加热轮采用电磁加热,热能损耗低、利用率高、加热快;

4.电器元件:国际品牌(RE、西门子、施耐德等),确保机器稳定,维修率低。

Features

1.Time-saving & effective:save time of paper folding by labor, can above 200% machine speed than single sheet art;

2.Less wastage:Reduce the wastage due to the single sheet cutting;

3.Energy-saving:adopt electromagnetic heating, less wastage of heat energy, high utilization;

4.Electric components:adopt international famous brand (like RE,SIMENS,Schneider etc) to make sure stable working and less repairing.

技术参数

| 型号 | HYGF -1100 | HYGF -1350 | HYGF -1650 |

幅面宽度 | 1000mm | 1300mm | 1600mm |

幅面宽度最小 | 400mm | 400mm | 400mm |

纸卷直径 | 1600mm | 1600mm | 1600mm |

使用纸张克度 | 60-500g/㎡ | 60-500g/㎡ | 60-500g/㎡ |

速度 | 150m/min | 150m/min | 150m/min |

纸卷重量 | 1200kg | 1200kg | 1200kg |

气压 | 6bar | 6bar | 6bar |

生产用电 | 25kw | 27kw | 30kw |

总用电量 | 50kw | 52kw | 55kw |

机械尺寸 | 8000mm*2930mm*3500mm | 8000mm*3130mm*3500mm | 8000mm*3280mm*3500mm |

机械重量 | 9000kg | 9600kg | 10500kg |

Technical Parameters

| Model | HYGF -1100 | HYGF -1350 | HYGF -1650 |

Max.roll width | 1000mm | 1300mm | 1600mm |

Min.roll width | 400mm | 400mm | 400mm |

Max.roll da | 1600mm | 1600mm | 1600mm |

Paper GSM | 60-500g/㎡ | 60-500g/㎡ | 60-500g/㎡ |

Speed | 150m/min | 150m/min | 150m/min |

Max.roll weight | 1200kg | 1200kg | 1200kg |

Air pressure | 6bar | 6bar | 6bar |

Production electricity | 25kw | 27kw | 30kw |

Total power | 50kw | 52kw | 55kw |

Machine size | 8000mm*2930mm*3500mm | 8000mm*3130mm*3500mm | 8000mm*3280mm*3500mm |

Machine weight | 9000kg | 9600kg | 10500kg |

机械配置

放纸机构

采用原纸架放纸、方便、平整

Unwinding section

Adopt base paper frame rolling, convenience & smooth

电磁加热系统

热能损耗低,利用率高,加热快。

Electromagnetic heating system

Electromagnetic heating system lower wastage of heat energy, higher utilization, faster heating.

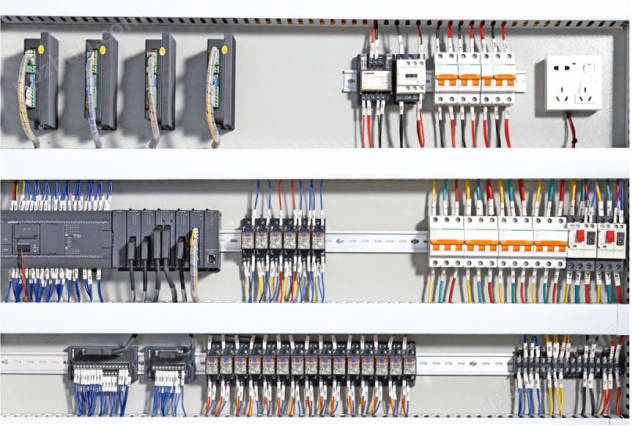

电柜箱

进口电子元件保证机器稳定,维修少等优点,电路采用PLC控制,按钮少操作简单,人性化设计。

Electric box

Imported electronic components ensure stable with less repairs. Circuit adopt humanity design with less repairs. Circuit adopt humanity design.

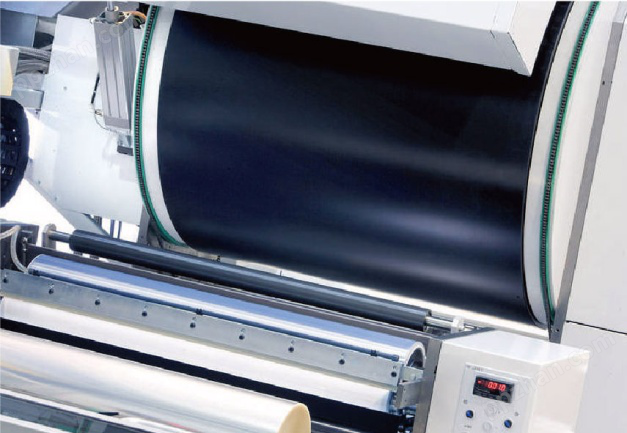

收卷机构

采用了气缸挤压式收卷,使卷径更大、更齐。

Winding section

Adopt air-cylinder extrusion winding, make rolling diameter bigger and trimmer.

涂胶装置

进陶瓷网纹轮及刮刀系统,保证上胶更均匀。

Coating device

Ceramic anilox roller & blade system, make sure more uniform gluing.

纠偏控制系统

光电纠偏/张力控制。

Correction control system

Photoelectric correction/tension control.

烘箱

干燥辊直径增加至Φ800薄膜干燥行程增加1倍多,前后烘箱自动控温,确保高速覆膜时烘干效果,有限节能30%。启动对开式结构,方便操作及日常维护。(热风循环,水汽分离)

Oven

The diameter of the drying roller is increased to Φ800. The drying stroke of the film is more than doubled. The front and rear ovens automaticaly control the temperature to ensure the drying effect at high speed, and the energy saving is 30%. Pneumatic open-type structure for easy operation and daily maintenance.