品牌

其他厂商性质

长沙市所在地

ZYXGF-200(150)洗灌塞旋自动生产线(直线型)

面议

YXGF-120洗灌塞旋自动生产线

面议

ZKGX系列灌装旋盖一体机(在线CIP/SIP功能)

面议

YT20/1000系列糖浆、合剂、洗液剂、酊水剂、酒剂联动生产线(100-300瓶/分钟)

面议

YT系列糖浆、合剂、洗液剂、酊水剂、酒剂联动生产线(60-150瓶/分钟)

面议

KSH系列隧道灭菌烘箱

面议

XFGXG32/30/16洗灌旋联动一体机(5-30ml塑料瓶口服液)

面议

FKGS系列灌装压盖一体机(5-30ml塑料瓶口服液)

面议

ZLP150(300)系列自动理瓶机

面议

FGXG系列负压式灌装旋盖一体机

面议

GCBX系列直列式灌装旋盖一体机

面议

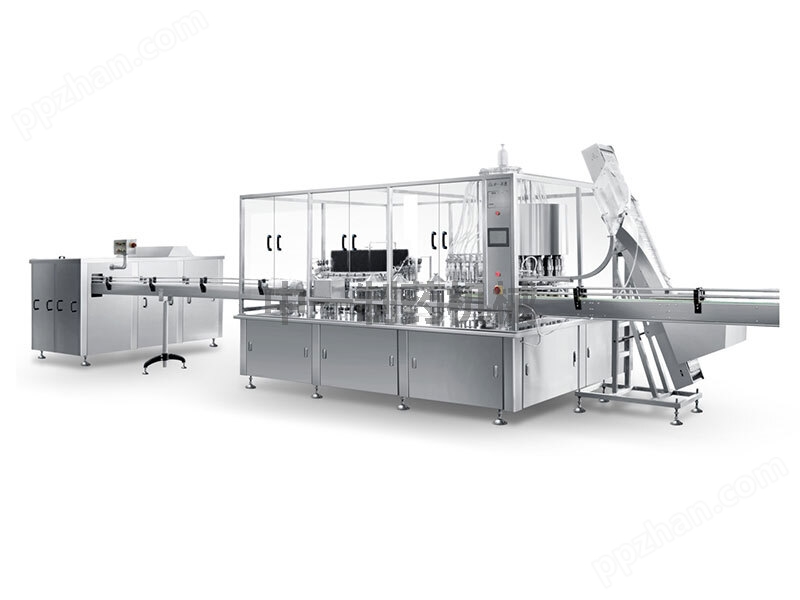

KXGF(A)5/30 系列口服液洗烘灌封联动线

面议主要用途:

该系列联动机组分洗瓶、灌装与热封三个工作区、可自动完成离子风气洗、(灌装前充氮)、管道式计量灌装、(灌装后充氮)、理盖、输盖、加热、焊盖接口等工序,主要适用于制药企业科研塑料瓶(BOPP瓶或非瓶非袋软瓶)大输液的生产。

Main Applications:

Linkage machine of this kind mainly includes three operation areas, namely, bottle-washing area, filling area. It can automatically complete such procedures as ion gas washing, (nitrogen filling before bottle filling), measuring filling, (nitrogen filling after bottle filling), lid arrangement, lid holding, heating, lid welding. It is mainly applied to the production of medical plastic bottles (BOPP bottles or soft bottles) in the pharmaceutical enterprises.

性能特点:

Performance characteristics:

主要技术参数:

Main Specifications: