品牌

其他厂商性质

长沙市所在地

ZYXGF-200(150)洗灌塞旋自动生产线(直线型)

面议

YXGF-120洗灌塞旋自动生产线

面议

ZKGX系列灌装旋盖一体机(在线CIP/SIP功能)

面议

YT20/1000系列糖浆、合剂、洗液剂、酊水剂、酒剂联动生产线(100-300瓶/分钟)

面议

YT系列糖浆、合剂、洗液剂、酊水剂、酒剂联动生产线(60-150瓶/分钟)

面议

KSH系列隧道灭菌烘箱

面议

XFGXG32/30/16洗灌旋联动一体机(5-30ml塑料瓶口服液)

面议

FKGS系列灌装压盖一体机(5-30ml塑料瓶口服液)

面议

ZLP150(300)系列自动理瓶机

面议

FGXG系列负压式灌装旋盖一体机

面议

GCBX系列直列式灌装旋盖一体机

面议

KXGF(A)5/30 系列口服液洗烘灌封联动线

面议主要用途:

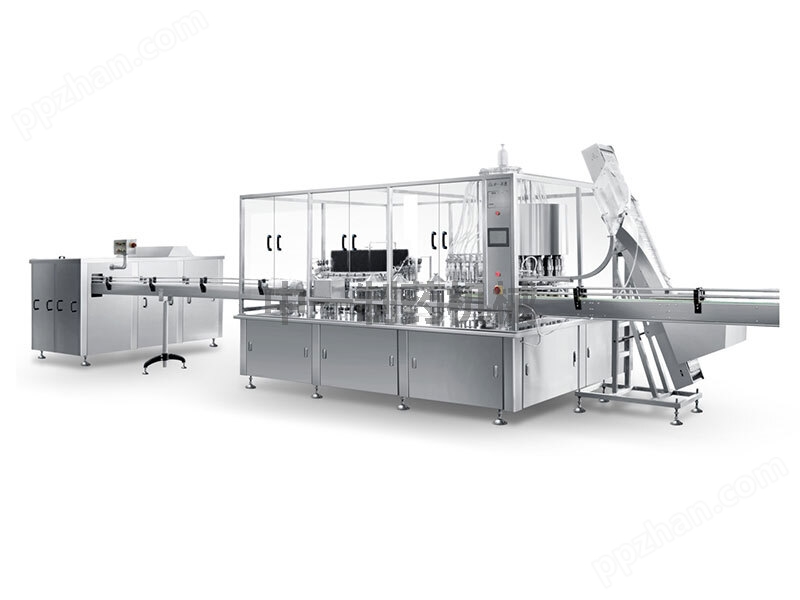

BNGGS系列大输液灌抽充塞联动机为玻璃瓶大输液生产中灌装、抽真空充氮气、加塞三个主体旋转工位合为一体的一台包装机。的管道式灌装、抽真空再充氮气、加塞部位采用真空抓塞,整机采用机械手夹持瓶颈定位并交接,该机器的设计不仅适用于普通大输液的生产,也立足于脂肪乳、氨基酸、中药注射剂及其它输液产品的生产,因此,除系统的本身要满足新版GMP的要求外,重点在灌装后抽真空充氮的方式上与原大输液灌装系统有着“质”的区别。

Main Applications:

BNGGS infusion filling-corking linkage machine is a packing machine that merges filling in infusion production, vacuumizing-nitrogenizing and corking in one. Advanced pipeline filling, vacuumizing- nitrogenizing, vacuum corking, and manipulator holding bottleneck to locate and connect make this design not only be applicable to ordinary infusion production but also to high point transfusion such as fat milk, amino acid, Chinese medicine injection, etc. It is different from the previous infusion filling system not only in satisfying the new GMP but also in the way of vacuumizing and nitrogenizing.

性能特点:

Performance Characteristics:

主要技术参数:

Main Technical Specifications: