1.Applications

This specifications is applied to relative humidity sensor Type SJL31.

Guaranteed impedance: 31kΩ at 25℃,60%RH

2.Ratings & electronic characteristics

Supply voltage: Less than AC5.0V AC1.0V is recommended.

Test wave shape: Sine or square wave shape.

With frequency 500~2,000Hz

1kHz is recommended.

Power consumption: Less than 2mW

Humidity range: 20-95%RH(in operation) 10-95%RH(in storage)

Temperature range: 0-50℃(in operation) -20-70℃(in storage)

Hysteresis: <2%RH

Response time

moisture absorption tim: <15S

moisture doffing time: <20S

Stability: <2%RH Per year

Interchangable characteristics: (-5%RH~5%RH)

Typical humidity sensor Characteristics: See following table 1

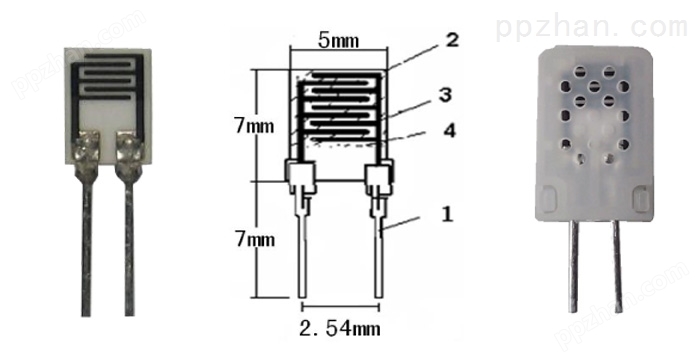

3.Outline Dimensions (Unit:mm)

4.Typical humidity sensor Characteristics(table 1)

| 0℃ | 5℃ | 10℃ | 15℃ | 20℃ | 25℃ | 30℃ | 35℃ | 40℃ | 45℃ | 50℃ |

20%RH | | | | 10M | 6700 | 4680 | 3900 | 3000 | 2400 | 1750 | 1450 |

25%RH | | 10M | 7000 | 5000 | 3400 | 2420 | 1900 | 1500 | 1100 | 880 | 700 |

30%RH | 6400 | 4600 | 3249 | 2350 | 1800 | 1260 | 1050 | 850 | 650 | 560 | 420 |

35%RH | 2900 | 2100 | 1428 | 1099 | 851 | 640 | 520 | 430 | 330 | 260 | 190 |

40%RH | 1450 | 1070 | 676 | 520 | 403 | 298 | 268 | 237 | 185 | 130 | 110 |

45%RH | 700 | 500 | 343 | 264 | 204 | 152 | 145 | 120 | 88 | 70 | 56 |

50%RH | 370 | 260 | 182 | 140 | 107 | 81 | 76 | 63 | 51 | 41 | 33 |

55%RH | 190 | 140 | 106 | 82 | 63 | 49 | 44 | 36 | 30 | 24 | 19 |

60%RH | 108 | 84 | 66 | 50 | 39 | 31 | 27.5 | 23 | 18.5 | 15.2 | 12.4 |

65%RH | 62 | 49 | 41 | 31.5 | 24.4 | 20 | 16 | 13.6 | 11.7 | 9.5 | 7.8 |

70%RH | 38 | 33 | 26 | 20 | 15.5 | 14.2 | 11 | 9.2 | 7.4 | 6.1 | 4.9 |

75%RH | 23 | 18 | 15.5 | 12.5 | 10.4 | 8.5 | 7.4 | 6.1 | 5.2 | 4.1 | 3.3 |

80%RH | 16 | 12.3 | 10 | 8.2 | 7.2 | 5.9 | 5.1 | 4.3 | 3.5 | 2.8 | 2.6 |

85%RH | 10.8 | 8.5 | 7.0 | 6.2 | 4.8 | 3.9 | 3.5 | 2.8 | 2.3 | 1.9 | 1.6 |

90%RH | 7.5 | 5.2 | 4.8 | 4.3 | 3.4 | 2.8 | 2.4 | 1.9 | 1.6 | 1.4 | 1.2 |

95%RH | 5.2 | 3.6 | 3.4 | 3.0 | 2.4 | 2 | 1.8 | 1.5 | 1.2 | 1.0 | 0.9 |

5.Packing

(1) 50PCS of sensor are placed in a tray

(2) 20sheets to be packed in a small carton box(SIZE:L190*W150*H55mm)(1,000PCS of sensor in a unit box)

(3) 16 small boxes to be packed in larager box(SIZE:L340*W390*H240mm)(16,000PCS of sensor in a lager box)

6.Mechanical durability

Drop test (Dropped onto wooden plate from a height of 1m, 3 times) | Passed |

Vibration test (Amplitude of 5mm, X, Y, Z directions, 10Hz for 20 min.) | Passed |

Tensile strength of lead wire (Pulled with 1kg load for 10 sec.) | Passed |

Lead wire bending test (lead wire was bended to 90 degreeswith 250g load, and bended again to opposite direction.) | Passed |

7.Reliability 1 (Temperature and humidity test)

Sensors were tested/stored in the conditions described below respectively, and the humidity characteristics at 25℃,60%RH before test and after test were inspected, and described in the following.

Test conditions | Variation |

1 | Sensors are stored in high temperature(80℃) for 1,000 hrs. | <±5%RH |

2 | Sensors are stored in low temperature(-20℃) for 1,000 hrs. | <±5%RH |

3 | Sensors are stored in high temperature and high humidity (50℃,90%RH) for 1,000 hrs. | <±5%RH |

4 | Sensors are stored in low humidity (25℃, less than 15%RH) for 1,000 hrs. | <±5%RH |

5 | Sensors are energized in high temperature(80℃) for 1,000 hrs. Supply voltage is AC1.0V, 1kHz. | <±5%RH |

6 | Sensors are energized in high temperature and high humidity (50℃,90%RH) for 1,000 hrs. Supply voltage is AC1.0V, 1kHz. | <±5%RH |

7 | 200 cycles of dewing condition for 10 minutes – drying condition for 10 minutes. | <±5%RH |

8.Reliability 2 (Organic solvent vapor, corrosive gases test)

Test conditions | Variation |

1 Methanol (1000ppm, 100 hrs.) | <±5%RH |

2 Ethanol (1000ppm, 100 hrs.) | <±5%RH |

3 Ammonia (1000ppm, 100 hrs.) | <±5%RH |

4 Acetic acid (1000ppm, 100 hrs.) | <±5%RH |

5 Mixed solvents (Benzene 3 : Toluene 3: | Xylene 4, 1000ppm, 100 hrs.) <±5%RH |

6 H2S (200ppm, 20 hrs.) | |

7 Acetone (1000ppm, 100 hrs.) | <±5%RH |

8 SO2 (200ppm, 20 hrs.) | <±5%RH |

9.Remarks

* Do not disassemble the sensor element.

* Do not supply direct current to sensor.

* Sensor is durable enough under high temperature / humidity or dew

* condensation conditions, but storage for an exceedingly long time under

* too severe conditions may cause improper functions.

* Polymeric humidity sensing layer may be damaged at 100℃ or more.

Refrain from using re-flow soldering systems.