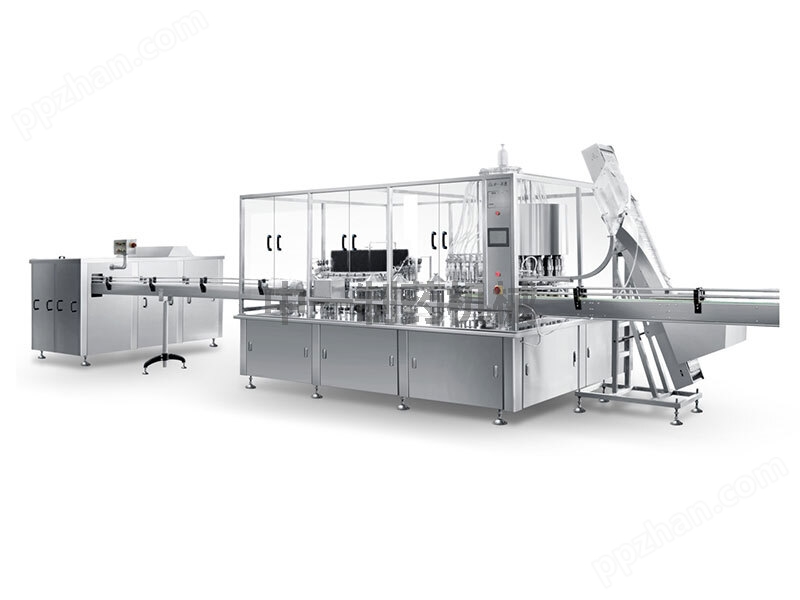

YT20/1000系列糖浆、合剂、洗液剂、酊水剂、酒剂联动生产线(100-300瓶/分钟)

产品简介

详细信息

该联动线主要由自动理瓶机、洗灌旋(离子风气洗+负压灌装+磁力旋盖)三位一体联动机、电磁感应封口机及不干胶贴标机组成,主要用来完成大容量口服溶液剂产品的整理、清除尘埃粒子、计量灌装、封口及贴标签等工序,整个生产过程在连续运转工作状态下进行,适用于塑料瓶,去除尘埃粒子,易产生泡沫,易滴漏,旋紧力度大,瓶子易擦伤并且产量要求高的产品。

This linkage production line is composed of the automatic bottle arrangement machine, washing, filling and capping (ion wind washing, negative pressure filling and magnetic force capping) machine, electromagnetic induction sealer and label sticker and is mainly used to arrange the large-capacity oral solution products, clean the dust particles, balance and fill, seal and stick mark. The linkage production process is completed under continuous operation state. This production line is suitable for removing dust particles of plastic bottle and those products which are easy to generate foam, drop, too high capping force and bottle scrape and require high quality.

其中三位一体联动机为同类机型国内创新产品,采用密封瓶口吹离子风除静电清洗瓶子,实现了塑料瓶口服溶液剂产品在灌装前的有效清洗,该清洗装置的应用提高了产品澄明度和产品合格率。灌装部分采用双室低真空负压等位灌装,旋盖部分采用磁力离合器旋盖,无滴漏、无泡沫溢出瓶口、无瓶不灌装、瓶底瓶肩紧装置、旋盖头旋紧瓶盖后自动离合等装置的应用,使联动机组在连续运转状态下有效减少了瓶与瓶撞击发生的荡液、滴液和歪盖的情况,有效控制了药液污染工作环境及包装材料的风险,并且保证其生产过程中符合GMP要求,是各液体制剂产品生产企业理想的联动生产线。

The three-function integrated machine is first invented in similar models in China. It can seal the bottle mouth and blow the ion wind to remove the static and clean the bottle and can effectively clean the plastic bottle oral solution products prior to filling. This cleaning machine improves the product clarity and product qualification rate. The filling part realizes the equivalent filling with the dual-chamber low vacuum negative pressure. The capping machine screws up the cap with the magnetic force clutch to avoid drop, overflowing foam at the bottle mouth and filling in case of no bottle. The bottle bottom and shoulder positioning and clamping machine and automatic clutch machine for the cap screwed up by the capping header are used to effectively reduce the liquid swinging, drop and tilting caused by impacting bottles when the linkage unit is continuously operating, effectively control the pollution of the pharmacy liquid to the working environment and packing materials and ensure that the production process meets GMP requirement, so it is the ideal for the liquid agent product manufacturers.

主要技术参数:

Main technical parameters:

- 生产能力:100-300b/min

- Productivity:100-300b/min

- 清洗/灌装/旋盖头数:40/40/16

- Cleaning/filling/capping header number:40/40/16

- 理瓶机功率:1.16Kw 380V 50Hz

- Power of bottle arrangement machine:1.16Kw 380V 50Hz

- 洗灌旋一体机功率:4.0Kw 380V 50Hz

- Power of cleaning, filling and capping maching:4.0Kw 380V 50Hz

- 水环真空泵功率:4.0Kw 380V 50Hz

- Power of water loop vacuum pump:4.0Kw 380V 50Hz

- 旋涡真空泵功率:3.0Kw 380V 50Hz

- Power of vortex vacuum pump:3.0Kw 380V 50Hz

- 铝箔封口机功率:4.0Kw 220V 50Hz

- Power of aluminum foil sealer:4.0Kw 220V 50Hz

- 贴标机功率:2.5Kw 220V 50Hz

- Power of label sticker:2.5Kw 220V 50Hz

- 生产线重量:~5300Kg

- Weight of production line:~5300Kg