不锈钢反冲洗高压泵

产品简介

详细信息

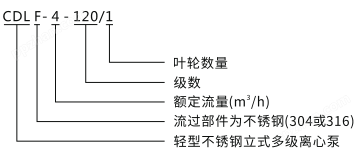

产品简介 型号意义 产品优势 性能参数 结构图纸 注意事项 原厂实图

1.高效节能:CDLF/CDL不锈钢轻型多级泵是采用丹麦技术制造而成,其是水力模型设计,高效率,高节能;

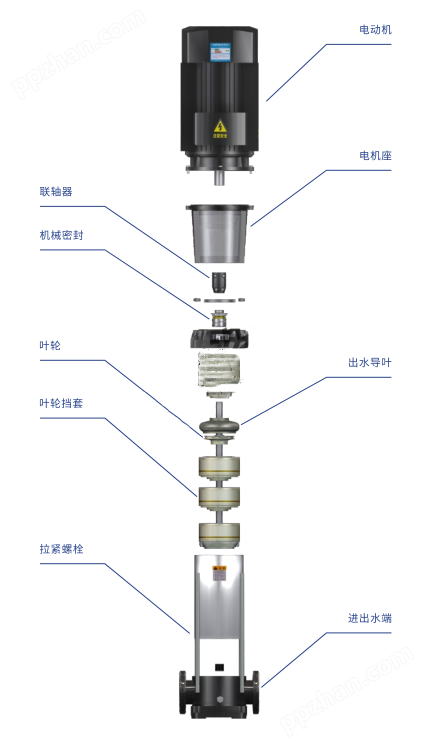

2.安装便捷:水泵内部叶轮、泵壳及其主要配件采用不锈钢冲压成形,流道特别光滑,轴瓦、轴套用硬质合金,具有的使用寿命,避免产生二次污染;

3.安装绝缘:轴封采用耐磨机械密封,无泄漏,电机采用Y2铅外壳,进口轴承,绝缘等级F级;

4.平稳可靠:外形美观、体积小、重量轻、运输安装方便;泵运转平稳,低噪音,整机质量可靠。

1、采用优良的水力模型和的制造工艺,大大提高泵的性能及使用寿命。

2、由于轴封采用材料为硬质合金及氟橡胶的机械密封,可提高泵运行的可靠性及输送介质的温度。

3、泵的过流部分采用不锈钢板冲压焊接而成,使得泵可适用于轻度腐蚀性介质。

4、整体结构紧凑、体积小、重量轻、噪声低、节能,检修方便。

5、泵的进水口与出水口位于泵座同一水平线上,可直接用于管路当中。

6、采用标准电机,用户可方便地根据需要配备电机。

7、可根据用户需要配备智能保护器,对泵干转、缺相、过载等进行有效保护。

| 型号 | 扬程 | 流量 | 电机功率 | 转速 |

| (m) | (m3/h) | (KW) | (r/min) | |

| CDL1-2 | 11.5 | 1 | 0.37 | 2900 |

| CDL1-3 | 17 | 1 | 0.37 | 2900 |

| CDL1-4 | 22.5 | 1 | 0.37 | 2900 |

| CDL1-5 | 28 | 1 | 0.37 | 2900 |

| CDL1-6 | 33.5 | 1 | 0.37 | 2900 |

| CDL1-7 | 39 | 1 | 0.37 | 2900 |

| CDL1-8 | 45 | 1 | 0.55 | 2900 |

| CDL1-9 | 51 | 1 | 0.55 | 2900 |

| CDL1-10 | 57 | 1 | 0.55 | 2900 |

| CDL1-17 | 95 | 1 | 1.1 | 2900 |

| CDL1-19 | 106 | 1 | 1.1 | 2900 |

| CDL1-21 | 117 | 1 | 1.1 | 2900 |

| CDL1-23 | 128 | 1 | 1.1 | 2900 |

| CDL1-25 | 139 | 1 | 1.5 | 2900 |

| CDL1-27 | 150 | 1 | 1.5 | 2900 |

| CDL1-30 | 166 | 1 | 1.5 | 2900 |

| CDL1-33 | 183 | 1 | 2.2 | 2900 |

| CDL1-36 | 200 | 1 | 2.2 | 2900 |

| CDL2-2 | 15 | 2 | 0.37 | 2900 |

| CDL2-3 | 22 | 2 | 0.37 | 2900 |

| CDL2-4 | 30 | 2 | 0.55 | 2900 |

| CDL2-5 | 37 | 2 | 0.55 | 2900 |

| CDL2-6 | 45 | 2 | 0.75 | 2900 |

| CDL2-7 | 52 | 2 | 0.75 | 2900 |

| CDL2-9 | 67 | 2 | 1.1 | 2900 |

| CDL2-11 | 82 | 2 | 1.1 | 2900 |

| CDL2-13 | 98 | 2 | 1.5 | 2900 |

| CDL2-15 | 112 | 2 | 1.5 | 2900 |

| CDL2-18 | 136 | 2 | 2.2 | 2900 |

| CDL2-22 | 165 | 2 | 2.2 | 2900 |

| CDL2-26 | 198 | 2 | 3.0 | 2900 |

| CDL3-2 | 9 | 3 | 0.37 | 2900 |

| CDL3-3 | 14 | 3 | 0.37 | 2900 |

| CDL3-4 | 19 | 3 | 0.37 | 2900 |

| CDL3-5 | 23 | 3 | 0.37 | 2900 |

| CDL3-6 | 28 | 3 | 0.55 | 2900 |

| CDL3-7 | 32 | 3 | 0.55 | 2900 |

| CDL3-8 | 37 | 3 | 0.75 | 2900 |

| CDL3-9 | 42 | 3 | 0.75 | 2900 |

| CDL3-10 | 47 | 3 | 0.75 | 2900 |

| CDL3-11 | 51 | 3 | 1.1 | 2900 |

| CDL3-12 | 55 | 3 | 1.1 | 2900 |

| CDL3-13 | 60 | 3 | 1.1 | 2900 |

| CDL3-15 | 69 | 3 | 1.1 | 2900 |

| CDL3-17 | 79 | 3 | 1.5 | 2900 |

| CDL3-19 | 88 | 3 | 1.5 | 2900 |

| CDL3-21 | 98 | 3 | 2.2 | 2900 |

| CDL3-23 | 107 | 3 | 2.2 | 2900 |

| CDL3-25 | 116 | 3 | 2.2 | 2900 |

| CDL3-27 | 124 | 3 | 2.2 | 2900 |

| CDL3-29 | 133 | 3 | 2.2 | 2900 |

| CDL3-31 | 142 | 3 | 3 | 2900 |

| CDL3-33 | 151 | 3 | 3 | 2900 |

| CDL3-36 | 168 | 3 | 3 | 2900 |

| CDL4-2 | 15 | 4 | 0.37 | 2900 |

| CDL4-3 | 24 | 4 | 0.55 | 2900 |

| CDL4-4 | 32 | 4 | 0.75 | 2900 |

| CDL4-5 | 40 | 4 | 1.1 | 2900 |

| CDL4-6 | 48 | 4 | 1.1 | 2900 |

| CDL4-7 | 56 | 4 | 1.5 | 2900 |

| CDL4-8 | 64 | 4 | 1.5 | 2900 |

| CDL4-10 | 81 | 4 | 2.2 | 2900 |

| CDL4-12 | 95 | 4 | 2.2 | 2900 |

| CDL4-14 | 112 | 4 | 3 | 2900 |

| CDL4-16 | 129 | 4 | 3 | 2900 |

| CDL4-19 | 153 | 4 | 4 | 2900 |

| CDL4-22 | 178 | 4 | 4 | 2900 |

| CDL8-2/1 | 9 | 8 | 0.75 | 2900 |

| CDL8-2 | 18 | 8 | 0.75 | 2900 |

| CDL8-3 | 27 | 8 | 1.1 | 2900 |

| CDL8-4 | 36 | 8 | 1.5 | 2900 |

| CDL8-5 | 45 | 8 | 2.2 | 2900 |

| CDL8-6 | 54 | 8 | 2.2 | 2900 |

| CDL8-8 | 73 | 8 | 3.0 | 2900 |

| CDL8-10 | 92 | 8 | 4.0 | 2900 |

| CDL8-12 | 111 | 8 | 4.0 | 2900 |

| CDL8-14 | 130 | 8 | 5.5 | 2900 |

| CDL8-16 | 148 | 8 | 5.5 | 2900 |

| CDL8-18 | 167 | 8 | 7.5 | 2900 |

| CDL8-20 | 186 | 8 | 7.5 | 2900 |

| CDL12-2 | 20 | 12 | 1.5 | 2900 |

| CDL12-3 | 30 | 12 | 2.2 | 2900 |

| CDL12-4 | 40 | 12 | 3 | 2900 |

| CDL12-5 | 50 | 12 | 3 | 2900 |

| CDL12-6 | 60 | 12 | 4 | 2900 |

| CDL12-7 | 70 | 12 | 5.5 | 2900 |

| CDL12-8 | 80 | 12 | 5.5 | 2900 |

| CDL12-9 | 91 | 12 | 5.5 | 2900 |

| CDL12-10 | 101 | 12 | 7.5 | 2900 |

| CDL12-12 | 121 | 12 | 7.5 | 2900 |

| CDL12-14 | 141 | 12 | 11 | 2900 |

| CDL12-16 | 162 | 12 | 11 | 2900 |

| CDL12-18 | 183 | 12 | 11 | 2900 |

| CDL16-2 | 22 | 16 | 2.2 | 2900 |

| CDL16-3 | 34 | 16 | 3.0 | 2900 |

| CDL16-4 | 46 | 16 | 4.0 | 2900 |

| CDL16-5 | 58 | 16 | 5.5 | 2900 |

| CDL16-6 | 70 | 16 | 5.5 | 2900 |

| CDL16-7 | 82 | 16 | 7.5 | 2900 |

| CDL16-8 | 94 | 16 | 7.5 | 2900 |

| CDL16-10 | 118 | 16 | 11 | 2900 |

| CDL16-12 | 141 | 16 | 11 | 2900 |

| CDL16-14 | 166 | 16 | 15 | 2900 |

| CDL16-16 | 189 | 16 | 15 | 2900 |

| CDL20-1 | 10 | 20 | 1.1 | 2900 |

| CDL20-2 | 23 | 20 | 2.2 | 2900 |

| CDL20-3 | 35 | 20 | 4.0 | 2900 |

| CDL20-4 | 47 | 20 | 5.5 | 2900 |

| CDL20-5 | 58 | 20 | 5.5 | 2900 |

| CDL20-6 | 70 | 20 | 7.5 | 2900 |

| CDL20-7 | 82 | 20 | 7.5 | 2900 |

| CDL20-8 | 94 | 20 | 11 | 2900 |

| CDL20-10 | 118 | 20 | 11 | 2900 |

| CDL20-12 | 142 | 20 | 15 | 2900 |

| CDL20-14 | 166 | 20 | 15 | 2900 |

| CDL20-17 | 202 | 20 | 18.5 | 2900 |

| CDL32-10-1 | 9 | 32 | 1.5 | 2900 |

| CDL32-10 | 13 | 32 | 2.2 | 2900 |

| CDL32-20-2 | 20 | 32 | 3.0 | 2900 |

| CDL32-20 | 27 | 32 | 4.0 | 2900 |

| CDL32-30-2 | 33 | 32 | 5.5 | 2900 |

| CDL32-30 | 40 | 32 | 5.5 | 2900 |

| CDL32-40-2 | 46 | 32 | 7.5 | 2900 |

| CDL32-40 | 53 | 32 | 7.5 | 2900 |

| CDL32-50-2 | 60 | 32 | 11 | 2900 |

| CDL32-50 | 67 | 32 | 11 | 2900 |

| CDL32-60-2 | 74 | 32 | 11 | 2900 |

| CDL32-60 | 81 | 32 | 11 | 2900 |

| CDL32-70-2 | 88 | 32 | 15 | 2900 |

| CDL32-70 | 95 | 32 | 15 | 2900 |

| CDL32-80-2 | 102 | 32 | 15 | 2900 |

| CDL32-80 | 109 | 32 | 15 | 2900 |

| CDL32-90-2 | 117 | 32 | 18.5 | 2900 |

| CDL32-90 | 124 | 32 | 18.5 | 2900 |

| CDL32-100-2 | 131 | 32 | 18.5 | 2900 |

| CDL32-100 | 138 | 32 | 18.5 | 2900 |

| CDL32-110-2 | 146 | 32 | 22 | 2900 |

| CDL32-110 | 153 | 32 | 22 | 2900 |

| CDL32-120-2 | 160 | 32 | 22 | 2900 |

| CDL32-120 | 167 | 32 | 22 | 2900 |

| CDL32-130-2 | 174 | 32 | 30 | 2900 |

| CDL32-130 | 181 | 32 | 30 | 2900 |

| CDL32-140-2 | 189 | 32 | 30 | 2900 |

| CDL32-140 | 196 | 32 | 30 | 2900 |

| CDL42-10-1 | 16 | 42 | 3.0 | 2900 |

| CDL42-10 | 20 | 42 | 4.0 | 2900 |

| CDL42-20-2 | 32 | 42 | 5.5 | 2900 |

| CDL42-20 | 41 | 42 | 7.5 | 2900 |

| CDL42-30-2 | 52 | 42 | 11 | 2900 |

| CDL42-30 | 61 | 42 | 11 | 2900 |

| CDL42-40-2 | 73 | 42 | 15 | 2900 |

| CDL42-40 | 81 | 42 | 15 | 2900 |

| CDL42-50-2 | 93 | 42 | 18.5 | 2900 |

| CDL42-50 | 101 | 42 | 18.5 | 2900 |

| CDL42-60-2 | 113 | 42 | 22 | 2900 |

| CDL42-60 | 122 | 42 | 22 | 2900 |

| CDL42-70-2 | 134 | 42 | 30 | 2900 |

| CDL42-70 | 142 | 42 | 30 | 2900 |

| CDL42-80-2 | 154 | 42 | 30 | 2900 |

| CDL42-80 | 162 | 42 | 30 | 2900 |

| CDL42-90-2 | 174 | 42 | 30 | 2900 |

| CDL42-90 | 183 | 42 | 37 | 2900 |

| CDL42-100-2 | 194 | 42 | 37 | 2900 |

| CDL42-100 | 203 | 42 | 37 | 2900 |

| CDL42-110-2 | 217 | 42 | 45 | 2900 |

| CDL42-110 | 225 | 42 | 45 | 2900 |

| CDL42-120-2 | 238 | 42 | 45 | 2900 |

| CDL42-120 | 247 | 42 | 45 | 2900 |

| CDL42-130-2 | 259 | 42 | 45 | 2900 |

| CDL65-10-1 | 13 | 65 | 4.0 | 2900 |

| CDL65-10 | 20 | 65 | 5.5 | 2900 |

| CDL65-20-2 | 26 | 65 | 7.5 | 2900 |

| CDL65-20-1 | 33 | 65 | 11 | 2900 |

| CDL65-20 | 40 | 65 | 11 | 2900 |

| CDL65-30-2 | 46 | 65 | 15 | 2900 |

| CDL65-30-1 | 53 | 65 | 15 | 2900 |

| CDL65-30 | 60 | 65 | 18.5 | 2900 |

| CDL65-40-2 | 66 | 65 | 18.5 | 2900 |

| CDL65-40-1 | 73 | 65 | 22 | 2900 |

| CDL65-40 | 80 | 65 | 22 | 2900 |

| CDL65-50-2 | 88 | 65 | 30 | 2900 |

| CDL65-50-1 | 95 | 65 | 30 | 2900 |

| CDL65-50 | 102 | 65 | 30 | 2900 |

| CDL65-60-2 | 110 | 65 | 30 | 2900 |

| CDL65-60-1 | 117 | 65 | 37 | 2900 |

| CDL65-60 | 124 | 65 | 37 | 2900 |

| CDL65-70-2 | 132 | 65 | 37 | 2900 |

| CDL65-70-1 | 139 | 65 | 37 | 2900 |

| CDL65-70 | 146 | 65 | 45 | 2900 |

| CDL65-80-2 | 154 | 65 | 45 | 2900 |

| CDL65-80-1 | 161 | 65 | 45 | 2900 |

| CDL85-10-1 | 14 | 85 | 5.5 | 2900 |

| CDL85-10 | 20 | 85 | 7.5 | 2900 |

| CDL85-20-2 | 30 | 85 | 11 | 2900 |

| CDL85-20 | 41 | 85 | 15 | 2900 |

| CDL85-30-2 | 52 | 85 | 18.5 | 2900 |

| CDL85-30 | 64 | 85 | 22 | 2900 |

| CDL85-40-2 | 75 | 85 | 30 | 2900 |

| CDL85-40 | 86 | 85 | 30 | 2900 |

| CDL85-50-2 | 98 | 85 | 37 | 2900 |

| CDL85-50 | 110 | 85 | 37 | 2900 |

| CDL85-60-2 | 122 | 85 | 45 | 2900 |

| CDL85-60 | 134 | 85 | 45 | 2900 |

| CDL120-10 | 18.5 | 120 | 11 | 2950 |

| CDL120-20-1 | 34.5 | 120 | 18.5 | 2950 |

| CDL120-20 | 40 | 120 | 22 | 2950 |

| CDL120-30 | 61 | 120 | 30 | 2950 |

| CDL120-40-1 | 76 | 120 | 37 | 2950 |

| CDL120-50-1 | 97 | 120 | 45 | 2950 |

| CDL120-60-1 | 118 | 120 | 55 | 2950 |

| CDL120-70 | 145 | 120 | 75 | 2950 |

| CDL150-10-1 | 12.5 | 150 | 11 | 2950 |

| CDL150-10 | 18.5 | 150 | 15 | 2950 |

| CDL150-20-1 | 35 | 150 | 22 | 2950 |

| CDL150-30-2 | 49 | 150 | 30 | 2950 |

| CDL150-30 | 63 | 150 | 37 | 2950 |

| CDL150-40-1 | 77 | 150 | 45 | 2950 |

| CDL150-50-2 | 92 | 150 | 55 | 2950 |

| CDL150-60 | 130 | 150 | 75 | 2950 |

注意事项

CDLF,QDLF立式轻型多级离心泵输送介质

1、稀薄、清洁、不含固体颗粒或纤维的非易燃易爆介质。

2、诸如矿泉水、软化水、纯水、清油和其他轻化工介质。

3、泵主要材料为不锈钢,可应用于抽送轻度腐蚀性介质。

使用条件:

1、介质温度:-15℃~ 120℃。

2、环境温度: 40℃。

3、环境压力:10bar。

4、进口压力受zui大环境压力限制。

5、当输送介质的密度或粘度大于水,需考虑配用较大功率的电机。

1、稀薄、清洁、不含固体颗粒或纤维的非易燃易爆介质。

2、诸如矿泉水、软化水、纯水、清油和其他轻化工介质。

3、泵主要材料为不锈钢,可应用于抽送轻度腐蚀性介质。

使用条件:

1、介质温度:-15℃~ 120℃。

2、环境温度: 40℃。

3、环境压力:10bar。

4、进口压力受zui大环境压力限制。

5、当输送介质的密度或粘度大于水,需考虑配用较大功率的电机。