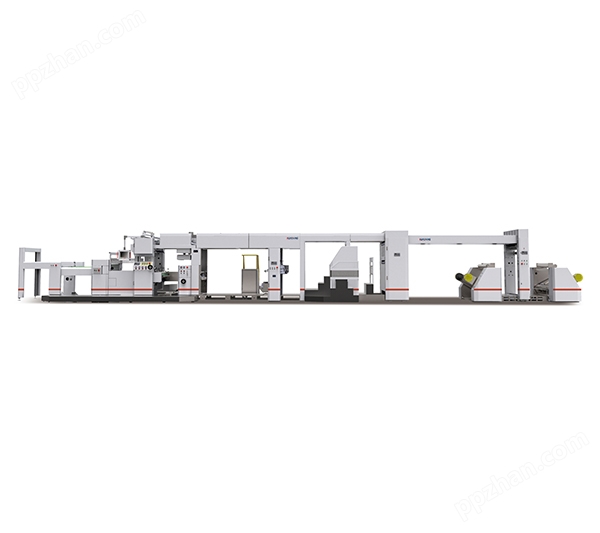

卷筒纸PUR聚氨酯胶覆膜机(收单张)PUR-HY1200

产品简介

详细信息

性能

卷筒纸PUR覆膜机是针对新工艺PUR聚氨酯胶水所设计的创机型,采用卷筒纸到单张的工作方式。PUR聚氨酯胶水涂布在薄膜上可同时在正面上光油(清漆),纸张放卷采用双工位不停机方式,纸张复合前可选择胶印(背面)、除尘、压光和加湿等多项工艺,两者在复合部采用常温方式贴合,贴合好的成品直接采用旋转刀裁切成单张,由自动收纸机整齐码垛收集。卷筒纸PUR覆膜机充分展示了PUR胶复合所带来的节能、高速、高品质、低成本等优势,一次性完成卷筒纸和薄膜成品的全部过程,可为用户节约大量的纸张和人工费用,是薄膜类产品加工的上佳选择。

Features

The web PUR laminator is the first domestic model designed for the new process PUR polyurethane glue. It uses a roll-to-sheet operation. PUR polyurethane glue is coated on the film can be varnished on the front side (varnish) at the same time, the paper unwinding adopts the double staion non-stop mode, and the offset can be selected before offset (back printing), dust removal, calendering and humidification. In the process, the two parts are laminated at normal temperature and low pressure in the composite part, and the finished products are directly cut into single sheets by a rotary knife, and are collected by the automatic delivery machine. The web PUR laminating machine fully demonstrates the advantages of energy saving, high speed, high quality and low cost brought by PUR adhesive compound, and completes all processes from web and film to finished products at one time, which can save a lot of users. Paper and labor costs are good choice for laminating products.

特点

1.高效:每分钟120米的生产速度(不胶印)(每小时可处理5000-12000张产能)。不停机接纸盒更换垛盘,保证生产的连续性,提高生产效率,减少损耗;

2.节能:PUR聚氨酯胶覆膜与传统的水性胶覆膜相对比,省去了水性胶覆膜后的烘干过程,从而大大节约了能源使用;

3.节约原料:采用不停机接纸和不停机换垛,版缝连续可调的卷筒纸胶印,减少损耗,节约原料;复合前纸张加湿使用每平方米施胶量能控制得更低;

4.绿色环保:绿色环保的聚氨酯(PUR)胶通过EDA认证,改写了覆膜非环保的历史;

5.*的工艺:一次性完成从卷筒纸和薄膜到成品的全部过程;

6.创新的技术:不停机接纸和更换垛盘实现了高效率和零浪费,宽幅面卷筒纸歇式胶印技术是胶印技术的新作;

7.出色的覆膜质量:常温的复合技术,避免因高温高压复合引起的薄膜与纸张变形,PUR胶水浸入纸张纤维,胶膜与纸张贴成一体,特别适合于专色覆膜。

Characteristics

1. High efficiency: production speed of 120 meters per minute (no offset printing) (processing capacity of 5000-12000 pieces per hour). To replace palletizing tray without stopping the machine, ensure the continuity of production, improve production efficiency and reduce loss;

2. Energy saving: compared with traditional water-based adhesive coating, PUR polyurethane adhesive coating saves the drying process after water-based adhesive coating, thus greatly saving energy use;

3. Save raw materials: adopt the web offset printing with continuous adjustment of the plate seam, reduce the loss and save raw materials; the amount of sizing per square meter before paper humidification can be controlled lower;

4. Green and environmental protection: the green and environmental polyurethane (PUR) adhesive has passed the EDA certification, rewriting the history of non environmental protection;

5. Perfect and advanced technology: complete the whole process from web and film to finished product at one time;

6. Innovative technology: it realizes high efficiency and zero waste by continuously receiving paper and changing pallets. The intermittent offset printing technology of wide web paper is a new work of offset printing technology;

7. Excellent laminating quality: the laminating technology at room temperature can avoid the deformation of the film and paper caused by high temperature and pressure lamination. The pur glue is completely immersed in the paper fiber, and the film and paper are pasted together, especially suitable for spot color lamination.

技术参数

| 型号 | PUR-HY 1200 |

纸张尺寸 | 1200*1020mm |

纸张克数 | 100-320g/㎡ |

放纸卷径 | 1500mm |

胶印主机速度 | 20-70m/min(5000-7000sheets/h) |

裁切精度 | ±0.3mm |

总重量 | 28T |

最小尺寸 | 350mm*450mm |

涂胶量 | 3-5g/㎡ |

放膜卷径 | 600mm |

不胶印主机速度 | 20-120m/min(5000-12000sheets/h) |

总功率 | 100kw(不使用涂布及烘干仅60kw) |

外形尺寸 | 21700*4200*3200mm |

Model | PUR-HY 1200 |

Max.sheet size | 1200*1020mm |

Weight of paper | 100-320g/㎡ |

Max.diameter of paper unreeling | 1500mm |

Speed of offset printing | 20-70m/min(5000-7000sheets/h) |

Cutting precision | ±0.3mm |

Total weight | 28T |

Min.sheet size | 350mm*450mm |

Glue amount | 3-5g/㎡ |

Max.diameter of film unreeling | 600mm |

Speed of non-offset printing | 20-120m/min(5000-12000sheets/h) |

Total power | 100kw(without coating and drying - 60kw) |

Overall size (L*W*H) | 21700*4200*3200mm |

机器配置

复合主机

常温复合技术,避免因高温高压复合引起的薄膜及纸张弯曲变形,PUR胶水浸入纸张,胶膜与纸张贴成一体,牢度大大加强。

Composite host

The normal temperature compounding technology avoid the bending deformation of the film and paper caused by the high temperature and high pressure composite;the PUR glue is completely immersed in the paper, and the film is integrated with the paper, and the fastness is greatly enhanced.

双座除粉单元

先采用双毛刷扫除纸张表面的灰尘和喷粉,再采用高温高压光镀铭辊把印刷表面凹凸不平的油墨、毛孔进行压光处理,对专色印刷品有更好的覆膜保障。

Tow-seat powder removing unit

Firstly, the double-brush is used to sweep off the dust and powder on the surface of the paper, and then the high-temperature calendering and polishing roller is used to calender the ink and pores of the printed surface, which has better film protection for the spot color print.

上光单元

采用逆向涂布方式,涂胶量的厚薄可以在人机界面上数字设定。

Glazing unit

By means of reverse coating, the thickness of the glue can be set digitally on the man-machine interface.

双回转螺旋刀

螺旋刀分切,可实现定位和定长分切。

Double rotary spiral knife

The spiral knife is cut to achieve positioning and fixed length slitting.

低胶水用量

胶水量可快速调节,提高生产效率,PUR胶水99%含固量,不损害地球生态环境,环保。

Low glue usage

The amount of glue can be quickly adjusted to improve production efficiency. PUR glue has 99% soild conent, does not damage the earth's ecological environment, and is completely, and if completely environmentally friendly.